The desperate Kaizen of outer space

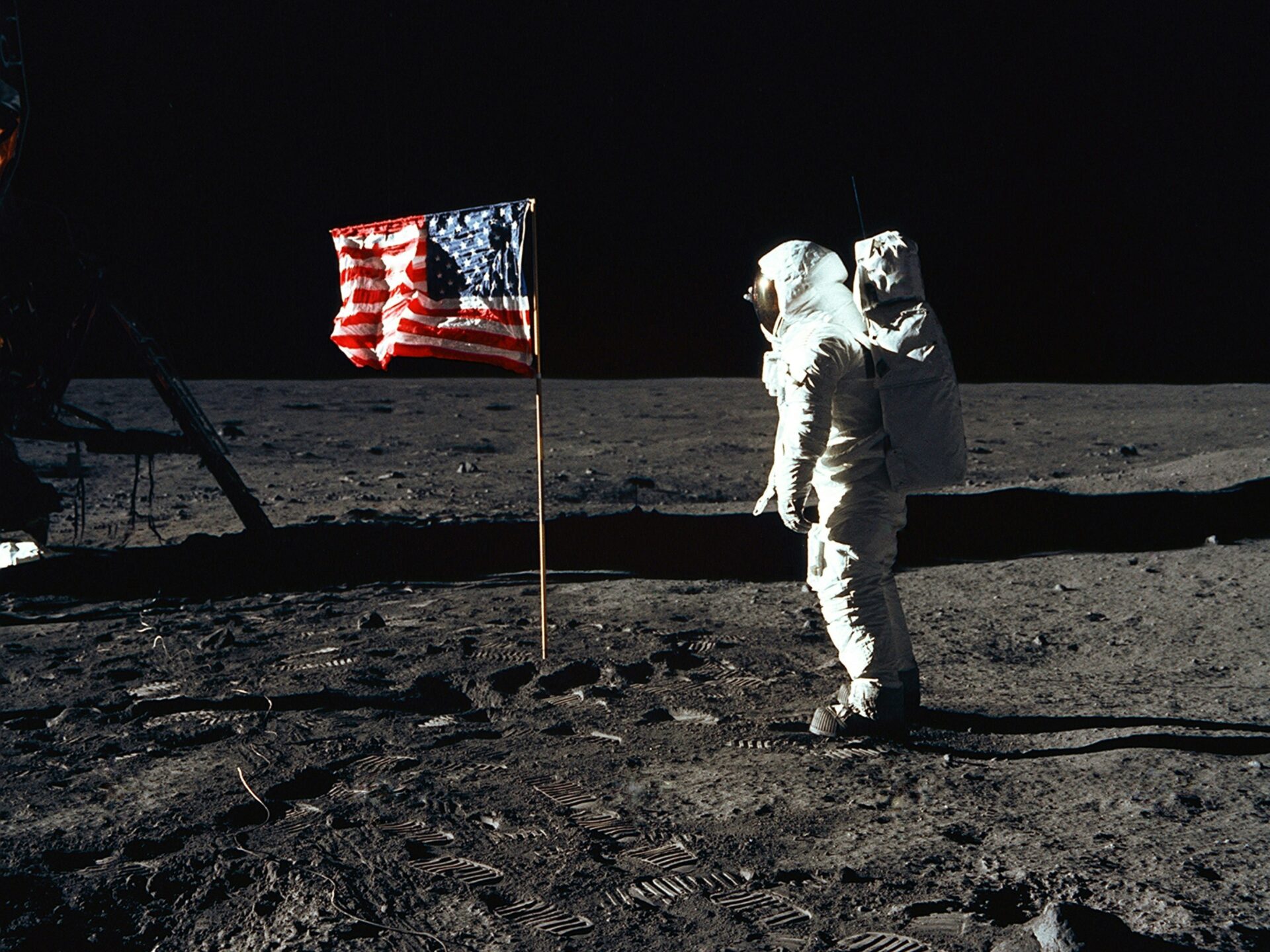

In the climax of the movie Apollo 13, the astronauts are hurtling toward Earth with a critically low power supply. Every second counts. In the windowless rooms of NASA, engineers frantically test every possible combination of activation sequences—skipping steps, re-routing circuits, and obsessively refining the process just to save a single watt of energy.

Watching Ken Mattingly (played brilliantly by Gary Sinise) overcome his frustration at being grounded due to suspected measles, only to pour his entire soul into saving his colleagues, reminds us of the true strength and beauty of human ingenuity. Of course, for some of us, Gary Sinise’s performance in Forrest Gump is so iconic that our memories get a bit mixed up. I can’t be the only one who occasionally thinks Lieutenant Dan somehow found his way from a shrimp boat into a NASA simulator. But regardless of the character, the message is clear.

This is the ultimate form of “Kaizen”—the Japanese philosophy of continuous improvement. When I watch the craftsmen in our factory engage in their own small Kaizen activities, I am often reminded of this scene. Though our scale is smaller, the tenacity is the same. But here’s the irony: while NASA was fighting to save lives, modern society often treats Kaizen like a race toward our own obsolescence.

The “low productivity” myth and the ghost of the MoF

Japan is frequently criticized for having the lowest labor productivity among OECD countries. Many Japanese people take this to heart, blaming themselves for a stagnant economy.

I don’t buy it for a second. In reality, our productivity only looks low because of thirty years of deflationary policy—a failure of the government, largely manipulated by the Ministry of Finance (my former workplace, I’m sorry to say). They remain haunted by the ghost of “potential inflation,” ignorantly tightening the purse strings while the rest of the world moves on. To us in the private sector, this isn’t a funny joke; it’s like trying to fly a spaceship while the ground crew is busy arguing about the cost of the fuel.

But more importantly: why are we so obsessed with “productivity” in the first place? Does a 2% increase in output actually bring us closer to a happy life?

Finding joy in the process, not the result

If the goal of productivity is simply “maximum efficiency,” then humans are destined to lose. Robots don’t need coffee breaks, they don’t have bad moods, and they certainly don’t get distracted by thoughts of what’s for dinner. If we define our value by productivity alone, we are declaring ourselves useless.

This is why I cherish the Kaizen sessions in our factory. When our craftsmen present their ideas for improvement, they aren’t just trying to save time. They are discovering hidden parts of themselves—someone discovers they are a natural facilitator; another finds a talent for public speaking or creative problem-solving.

The value of Kaizen isn’t the efficiency it creates; it’s the human growth that happens during the attempt. We shouldn’t improve productivity to become better “machines.” We should do it to find joy in the process of creation. At CondeHouse, we don’t aim for the cold perfection of a robot; we aim for the warm, slightly “inefficient” satisfaction of a human who has mastered their craft. In the end, it’s not the destination (the atmospheric re-entry) that defines us, but the ingenuity we show during the flight.

From a purely “productive” standpoint, the Hatsune Miku Art Chair is an exercise in beautiful inefficiency. Where a robot would prioritize speed and cost, our craftsmen spend countless hours perfecting every curve, pouring their soul into a design that defies mass production. Much like Ken Mattingly—or “Lieutenant Dan”—tenaciously solving the impossible in a NASA simulator, this chair is a victory of human ingenuity over cold logic. Choosing this seat is a quiet protest against the cult of productivity; it’s a throne for those who value the “process” of creation and the warmth of human passion over the soulless perfection of a machine.

Shungo Ijima

Global Connector | Reformed Bureaucrat | Professional Over-Thinker

After years of navigating the rigid hallways of Japan’s Ministry of Finance and surviving an MBA, he made a life-changing realization: spreadsheets are soulless, and wood has much better stories to tell.

Currently an Executive at CondeHouse, he travels the world decoding the “hidden DNA” of Japanese culture—though, in his travels, he’s becoming increasingly more skilled at decoding how to find the cheapest hotels than actual cultural mysteries.

He has a peculiar talent for finding deep philosophical meaning in things most people ignore as meaningless (and to be fair, they are often actually meaningless). He doesn’t just sell furniture; he’s on a mission to explain Japan to the world, one intellectually over-analyzed observation at a time. He writes for the curious, the skeptical, and anyone who suspects that a chair might actually be a manifesto in disguise.

Follow his journey as he bridges the gap between high-finance logic and the chaotic art of living!

Photo Credit: https://unsplash.com/ja