Wood lathe craftsman in Hokkaido

The other day, I attended a trila session of wood lathe. It was a rare opportunity to learn from a veteran craftsman, who has 60 years of experience in this field. Until a decade ago, all the legs of chairs and beds were handmade with a lathe. Asahikawa is known as a town of woodworkers, and there used to be dozens of craftsmen who handled such wood lathes and opened workshops. Mr. Abe, the instructor of this workshop, is one of them, and his Christmas trees are popular in online stores.

Christmas trees crafted with lathe, designed by Abe Yasunori

Asahikawa craft center

The class was held at the Asahikawa Craft Center. Since woodworking is a major industry in the city, the municipality has established a product testing center for crafts. The Craft Center is located in a quiet ground on a hill, called Asahikawa Research Park. Inside the Craft Center, there were many processing and testing machines lined up.

Wait, milling a spinning tree by hand?

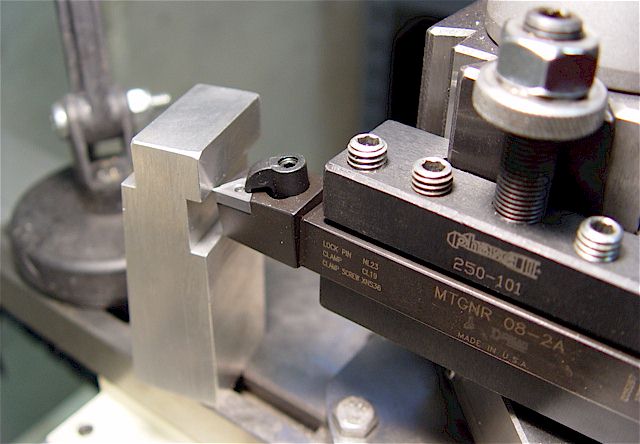

At the workshop, in the beginning the instructor gave a demonstration. Have you ever seen a wood lathe? What a surprise! When using a wood lathe, the blade is held and supported only by the hand. I used to do metalworking at my old job, and in metalworking we use a bit holders and tool post like the photo below. I never thought I’d be freehand on a wood lathe…

The metapher of “like tofu…”

But with Mr. Abe’s technique, the wood attached to the rotary is milled away like tofu! Well, the tofu analogy may be confusing for you, but it is like a pudding made of soy milk. The sppining tops were created with eye-popping speed. It’s hard to tell from the photo, but the surface is super smooth and grocy, shaved with moderate pressure using a well cutting blade.

Impressions of the wood lathe

Then it was time for hands-on experience. The levels of our paticipants ranged from beginner like me to intermediate. I was so afraid of being burst that my arms put unnecessary pressure to the material. On the second day, I could somehow carve the wood but the surface remained bumpy. Mr. Abe’s speed, accuracy, and beauty of the finished product were perfected in 60 years. It would be a regrettable loss of this technique, so I hope to see it succeeded. If there will be more hands-on workshops held, I would like to join again.

Photo credit: http://www.asahikawacraft.com/koubou/abekiji.html, https://www.micro-machine-shop.com/quick_change_tool_post_tool_bits.htm#Tool_Bit_Height_Gages, https://www.homedit.com/wood-lathe/

Nami